5.1 The preparatory works before the operation

5.1.1 Make sure that the surface of the specimen should be smooth and clean without any dirt, oxidized layer, sunken spot or processing trace. The supporting surface of the specimen and the plane of the testing table should be clean in order to have an intimate touch.

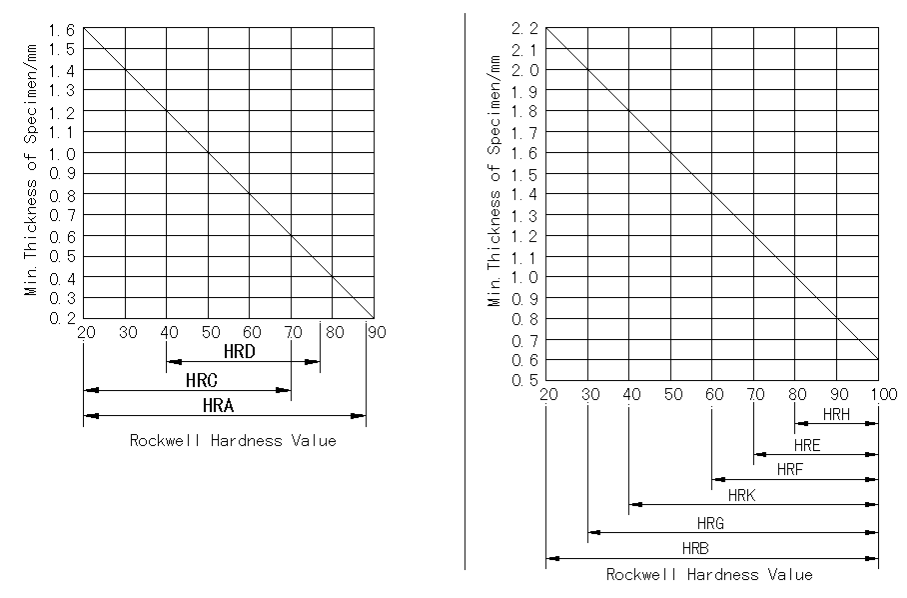

5.1.2 The min. thickness of the specimen should be more than 10 times greater than the depth of the indentation. After the test, there should be not visible deformed traces on the back of the specimen. For the relation between the min. thickness of the specimen and the hardness (see Fig. 5).

5.1.3 The specimen should be steadily placed on the testing table and should not be slightly moved during the operation of loading and unloading the test force so as to assure that the test force falls on the specimen vertically.

5.1.4 Choose the suitable testing table according to the shape and dimension of the specimen. If the specimen has an irregular shape, it is necessary to make by our selves the fixture according to its actual geometrical shape in order to obtain a reliable hardness value.

5.1.5 In case the specimen is a cylinder in shape, it is necessary to use the V-shaped testing table.

Name: Mikrosize

Mobile:0086-13918745376

Tel:0086-769-85331789

Email:mikrosize@188.com

Add:NO7 East Xingfa Road Wusha, Changan Town, Dongguan, China.