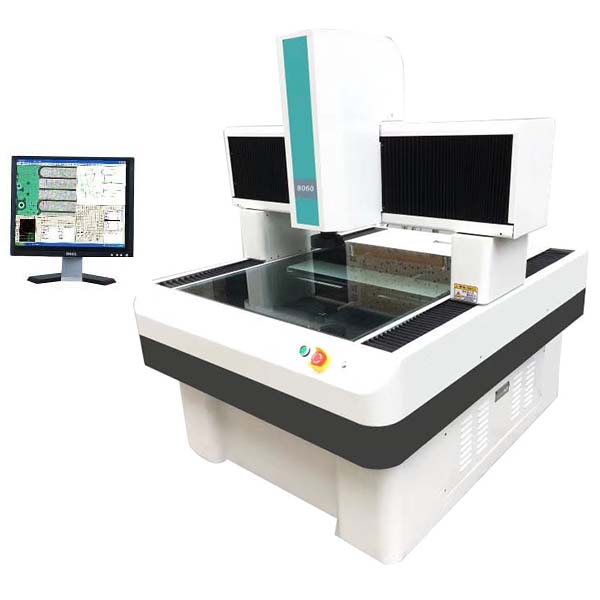

CNC Fully automatic video measuring system is a modern optical non-contact measuring instrument developed on the basis of digital video measuring system (also known as CNC imager). It inherits the excellent motion accuracy and motion control performance of digital instruments, integrating the design intelligence of machine vision software, and it belongs to the most advanced optical dimension detection equipment nowadays.

CNC Fully automatic video measuring system can quickly and conveniently carry out three-dimensional coordinate scanning measurement and SPC results classification, meet the increasingly prominent requirements of modern manufacturing industry for size detection: higher speed, more convenient, more accurate measurement needs, and solve another bottleneck technology in the development of manufacturing industry.

CNC Fully automatic video measuring system is an advanced stage of video measuring technology, which has the characteristics of high intelligence and automation. Its excellent hardware and software performance makes coordinate size measurement convenient and comfortable. It has the automatic learning function based on machine vision and process control. With the high-speed and accurate micro-level positioning of digital instruments, it can learn and memorize the path of measurement process, focusing, selecting points, function switching, manual correction, light matching and other operation processes. Fully automatic video measuring system can easily learn all the operation process of operators, and realize artificial intelligence by combining its automatic focusing and region searching, target locking, edge extraction, and fuzzy operation of point selection. It can automatically correct the offset caused by the difference of workpiece and position to achieve precise point selection with high accuracy and repeatability. Thus, operators can be freed from the monotonous operations such as accurate visual alignment of fatigue, frequent selection of points, repetitive positioning, function switching and the increasingly onerous tasks to be tested, which can improve the efficiency of batch testing hundreds of times and meet the needs of industrial sampling and mass testing.

The automatic video measuring system has three modes: manual measurement, CNC scanning measurement and automatic learning measurement, and can overlap the three modes of modules for composite measurement. It can scan and generate bird's-eye view image map, realize full-screen target traction of where to go and where to go. The result of measurement is synchronized with the image map. It can click on the image to return automatically and enlarge the full-screen hawk's eye. The imaging errors of any measured size can be corrected and calibrated through the actual measurement of the standard parts, so as to improve the batch measurement accuracy of key data. Fully automatic video measuring system has friendly man-machine interface, supporting multiple selection and learning correction.

The excellent performance of automatic video measuring system enables it to be used in various precision electronics, wafer technology, cutting tools, plastics, springs, stamping parts, connectors, moulds, military industry, two-dimensional reading, drawing, engineering development, hardware and plastics, PCB board, conductive rubber, powder metallurgy, screw, clock parts, mobile phones, pharmaceutical industry, optical fiber devices, automotive engineering, aerospace, colleges and universities. It has wide application space in scientific research institutes and other fields.

Name: Mikrosize

Mobile:0086-13918745376

Tel:0086-769-85331789

Email:mikrosize@188.com

Add:NO7 East Xingfa Road Wusha, Changan Town, Dongguan, China.